The Best Strategy To Use For Digital Printing

The Best Strategy To Use For Digital Printing

Blog Article

Indicators on Digital Printing You Should Know

Table of ContentsEverything about Digital PrintingExcitement About Digital PrintingThe Buzz on Digital PrintingDigital Printing - QuestionsAll About Digital PrintingDigital Printing Can Be Fun For AnyoneWhat Does Digital Printing Mean?

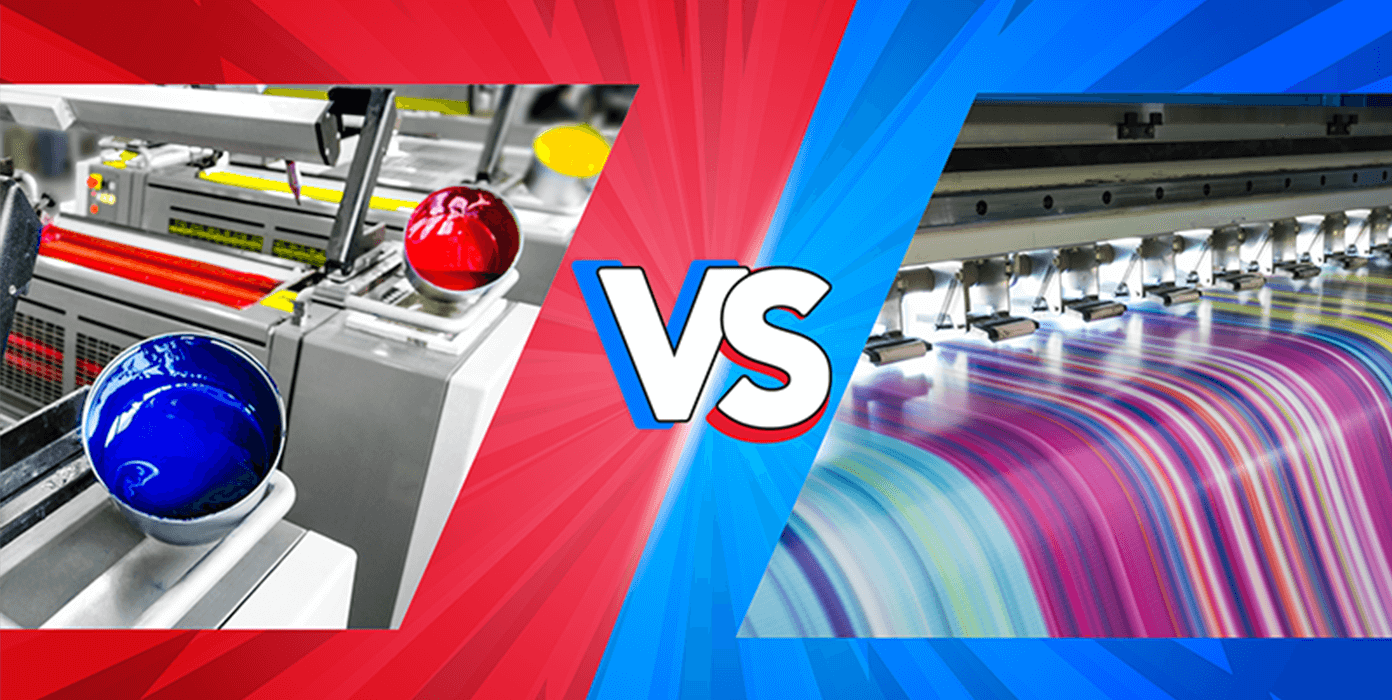

Unlike balanced out printing (or lithography), electronic printing does not utilize damp ink to move photos using printing plates (Digital Printing). Rather, electronic printers make use of a picture documents, such as a PDF, to draw up the and recreate it. Arrangement is much faster than offset printing, as there are no plates to develop and the electronic printer manages whateverToner-based presses use electrophotography, or powder-based pigmented toner that's gotten by an electrical drum and rolled onto the paper or product. Particles that develop a photo are then merged to the material utilizing a laser. Toner-based presses were the initial digital printing technique and remain to remain preferred today as a result of their capability to produce high-definition outcomes and print on a vast array of products.

The inkjet printing procedure entails liquid ink cartridges and nozzles that spray ink out in a haze over a designated photo or pattern. Inkjet modern technology has actually advanced swiftly since its innovation and is currently used in commercial applications such as textile printing, signs, and porcelains, as well paper. The most up to date generation of inkjet presses are capable of creating high quality that goes beyond Toner-based presses and even conventional balanced out presses.

All that's needed to produce an electronic print is a high-res picture file. Once that has actually been uploaded, the printer manages the rest, greatly lowering turnaround times for jobs that don't need significant amounts. If your job has a limited due date, electronic printing might be an excellent choice to check out.

Digital Printing Fundamentals Explained

The new generation of inkjet presses, like Fuji's J Press, are qualified of printing at a high quality degree, color gamut, and consistency that goes beyond even the best standard offset presses. When timing is a concern, electronic printing can be a wonderful alternative. If your project includes a larger amount (i.e.

The 8-Minute Rule for Digital Printing

We've covered the gamut of range printing advantages and disadvantages.

Digital printing is scalable for low and high volumes. For highly outlined, aesthetically appealing applications such as prime tags, digital printing guarantees top quality and uniformity, no matter exactly how big the quantity.

A Biased View of Digital Printing

It makes use of less products and creates less waste, as there's no requirement for plates or excess ink (Digital Printing). In addition, electronic printing enhances the deinkability and recyclability of published products. Digital printing is functional for numerous printing products and thicknesses. Digital printing guarantees outstanding attachment on a range of substrates. It likewise provides high readability, which is critical for sending information in industrial applications.

Digital printing provides extra adaptability and imaginative possibility. VDP can include security, traceability, and SKU range to printed materials. It can additionally be utilized to tailor specific items in a solitary print run, such as themed or seasonal graphics. Various other printing approaches require significant time for the ink to dry, yet electronic printing dries quickly.

Digital printing is a great selection when it concerns following strict food contact and security guidelines. Some printing can be non-toxic and odorless for food packaging applications. This distinct feature is vital for adhering to FDA and company printing guidelines. Being non-toxic, some electronic printing abide by safety and security requirements for kids's toys and apparel.

Our cutting edge tools enables us to print applications with resolutions of approximately 1,200 dpi and up to 98 ft. more helpful hints per minute. Our electronic printing provides exceptional lightfastness, one-pass nontransparent white, a broad selection of colors, and the satisfaction of being unsmelling, food-safe, and environmentally friendly. Apart from our printing abilities, Tapecon offers top-notch solution and experience.

8 Simple Techniques For Digital Printing

With over 100 years of producing experience, Tapecon functions with product groups to fix challenges, create products, and improve lives. Discover more concerning our durable printing and layer solutions.

Plateless digital printing makes feasible multi-product, low-volume printing in a restricted printing time and more affordable. A limited printing time enables numerous printing line of gabs, depending on private demands, creativeness or seasons.

Different design opportunities with complete shade and rank print without the limitation of shades. Full shade print is done in one process without utilizing plates. It allows fast shipment. It is currently feasible to create a solitary example which have the very same quality when compared the end product with the original layout.

How Digital Printing can Save You Time, Stress, and Money.

Analog printing needs times for color matching prior to starting the production. In electronic printing that time is no needed.

Variable data printing and customized manufacturing is also possible. The requirements of the consumers can be currently swiftly solutioned to, depending upon their very own leisure activities or seasons. In addition to the standard shade prints, the UV inkjet printers enable shiny coating, texture print, and embossed effects which includes much more value to the printed materials.

Table Of Component Litho Lamination (Offset Printing) is a standard printing method and was the most prominent choice up until recently. Litho is the procedure of printing onto paper lining board and then laminating that onto corrugated paper. Making use of oil and water, it produces a positive and adverse plate to transfer top quality shade graphics onto ideal substrates.

Not known Factual Statements About Digital Printing

The positive plate, with its smooth surface, attracts oil-based inks and repels water. In comparison, the adverse plate, with its harsh structure, soaks up water and pushes back oil. Rubber rollers are then made use of to transfer the picture from the plate to the corrugated surface.

Corrugated paper can occasionally confirm to be a challenging surface to print on, yet Litho prints to a different surface area and is then laminated flooring to it, making it simple to publish high-quality photos. It can be exceptionally constant, also for long terms. Actually, the more you print, the less costly the prices come to be for Litho.

Report this page